TYPES OF TILES

All the ceramic tiles produced by Zorka Keramika in accordance with the latest edition of European Standard EN 14411.

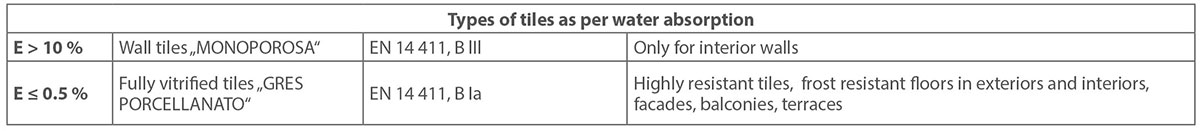

Glazed wall tiles and glazed wall decorations with water absorption E > 10 % – Group B III, with parameters conforming to EN 14411.

These tiles are designed for tiling wall interiors with temperatures above 0 °C, the tiles are not frost proof.

Glazed tiles and glazed floor decorations with water absorption E < 0.5 % = Gres Porcellanato Smaltato – Group B Ia, with parameters conforming to EN 14411. These tiles are designed for interior and exterior tiling in residential housing and public utility buildings. The tiles are characterized by low water absorption, high resistance to bending, high hardness and resistance to abrasion.

All the floor tiles produced by Zorka Keramika are of the Gres Porcellanato type.

CRITICAL TECHNICAL PROPERTIES OF CERAMIC TILES

Water absorption and frost resistance

Water absorption is the most important property for selecting the appropriate tile for a particular application, especially in wet environments or in areas subject to freeze/thaw cycles. Generally, the lower the water absorption, the higher the frost resistance, compactness and hardness of the tile.

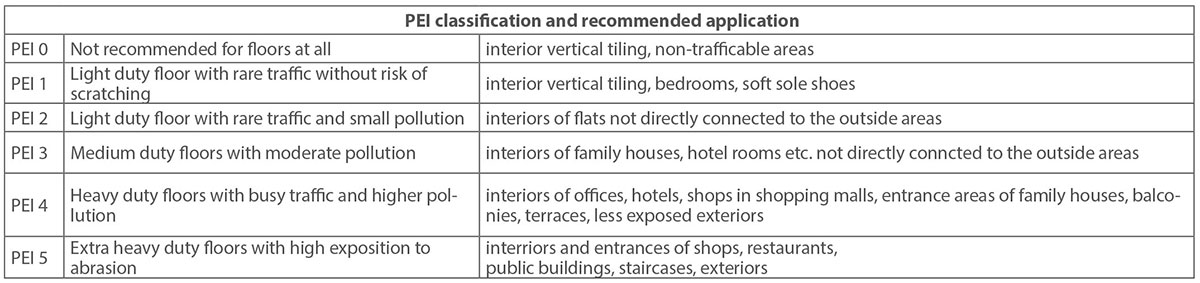

Abrasion resistance (PEI)

The abrasion resistance of glazed tiles is one of the decision-making parameters for the choice of an appropriate tile. Abrasion resistancemarks the resistance of the tile surface to mechanical wear and tear. The higher the mechanical and pollution exposure of the floor andpedestrian traffic, the higher abrasion resistance is desired. Particularly hard dirt particles from streets or gardens gradually abrade thesurface of tiles and irreversible changes in their appearance may occur. The standard EN ISO 10545-7 classifies abrasion resistance withclasses/degrees from 0 to 5. The information about abrasion resistance is indicated next to the floor tile picture.

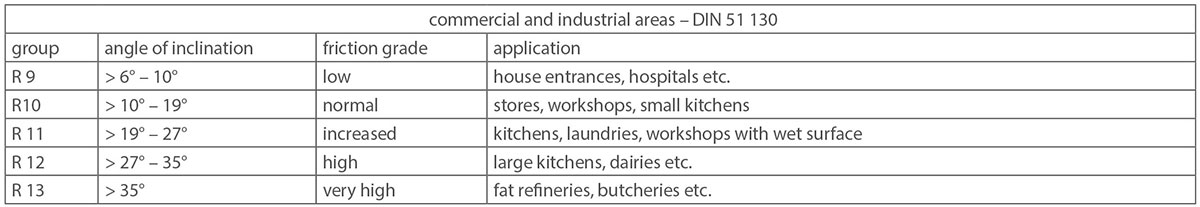

Slip resistance

For some areas, the safety consideration is even more critical than for others. There is a responsibility for stakeholders involved in specifying flooring products (manufacturers, architects, distributors, installers etc.) to ensure that the surfaces are fit for the purpose and do not pose a safety risk for the users.

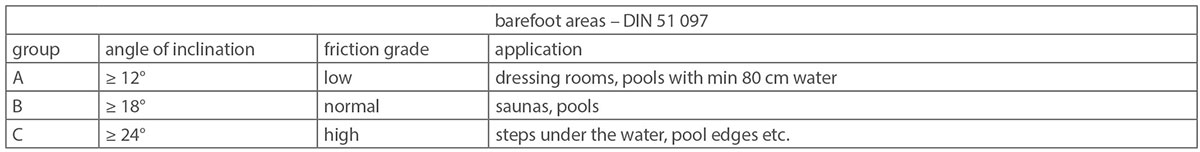

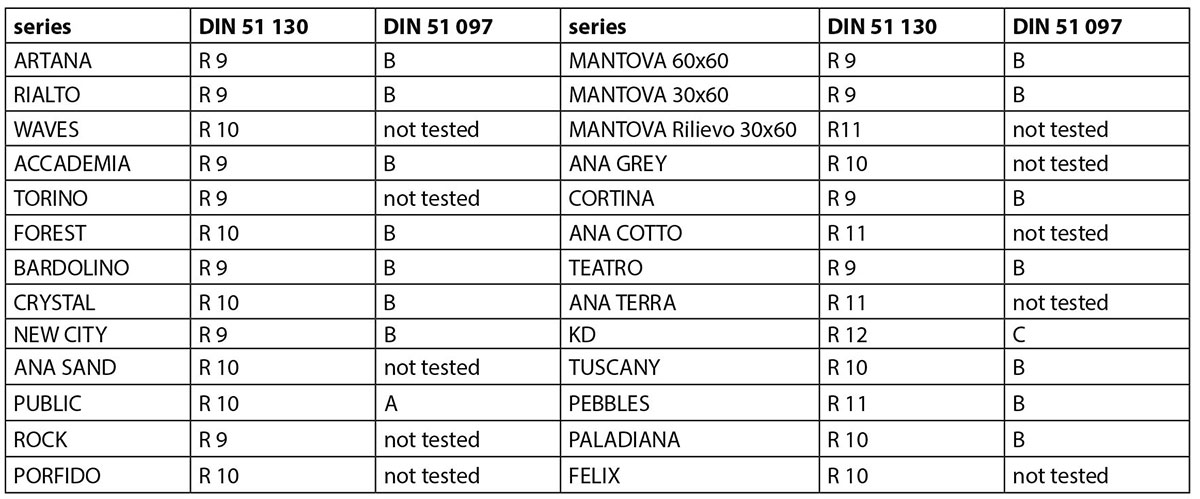

There is no uniform testing method in the EU and there are different requirements defined for anti-slip tile surfaces for areas walked on when wearing shoes (DIN 51 130) or when barefoot (DIN 51 097). Both tests are done on an inclined plane.

For such special applications, e.g. high-traffic halls, entrances, industrial areas, kitchens, workshops, wellness areas etc. Zorka KeramikaFor such special applications, e.g. high-traffic halls, entrances, industrial areas, kitchens, workshops, wellness areas etc. Zorka Keramikahas developed some products fulfilling the above-mentioned requirements as follows:

If the color is not explicitly stated the anti-slip value is valid for all the colors of the respective series. The certificate proving the above values can be found in the chapter titled Certificates.

Please note that the anti-slip surface of products results in a more demanding cleaning of the tiles.

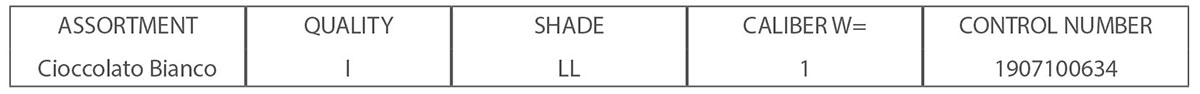

PRODUCT IDENTIFICATION ON THE BOXES

The tiles are packed in carton boxes. The 1st choice is marked as follows:

Name of item/design - Corresponds to the name stated in the catalogue

- Quality - Usually 1 choice = 1, standard choice = S

- Color shade/version - This is an immanent and typical attribute of all ceramic tiles. During the firing process more versions may occur – the color may range in intensity, shade and surface texture, however the character of the design must be preserved.

- Please observe – wall tiles, floor tiles and decors produced by modern rotocolor technology may show slight differences in pattern, color shade and intensity that are desirable and characteristic for a particular design.

In order to get the best effect, only one color shade must be used on the same area. Shade identification is applied mostly only for the 1st choice products. - Calibre - The number describing the dimension group of a tile within the dimensional tolerance given by the standard. In order to get the best effect, only one shade must be used on the same area. Calibre identification is mostly applied only for the 1st choice products.

- Control number - A number enabling production identification. This information is essential in the event of any claims.

When tiling, it is strictly recommended to use only tiles in one shade and in the same calibre for the same area. Prior to tiling and opening and mixing the tiles from different boxes is recommended.

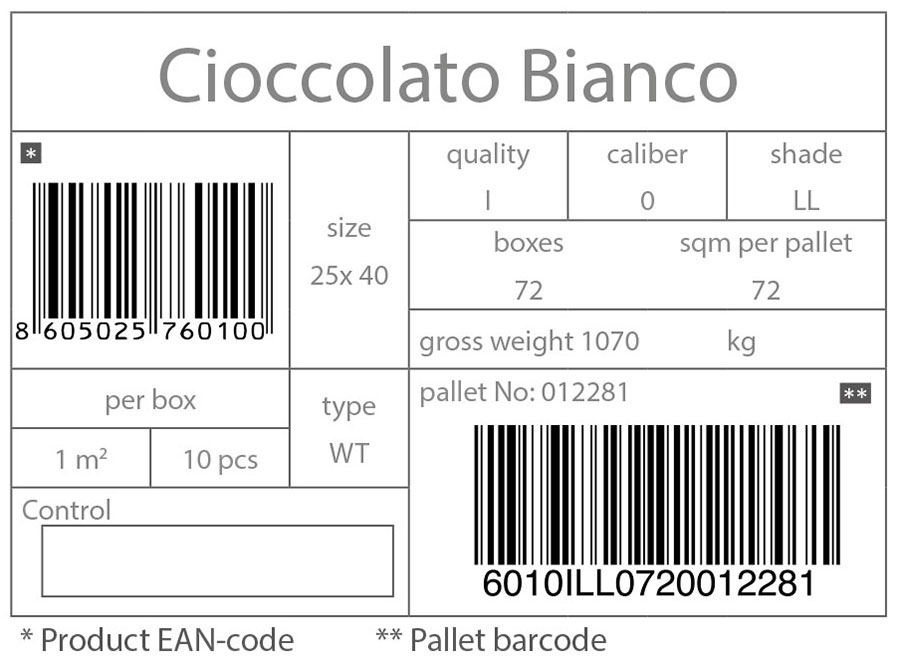

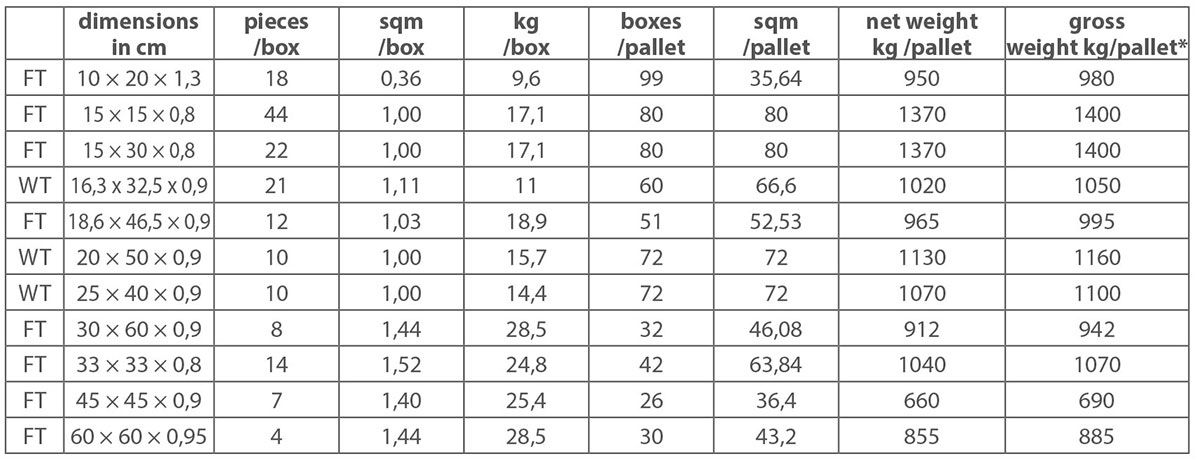

Boxes are loaded on one-way pallets in dimensions of 120 x 80 cm with a label as follows:

Logistic data

- incl. weight of a wooden pallet / ± 5%* incl. weight of a wooden pallet / ± 5%

- The packing data for decors – listels, insertos and cut pieces – are always shown below the picture of the decor directly in the catalogue.

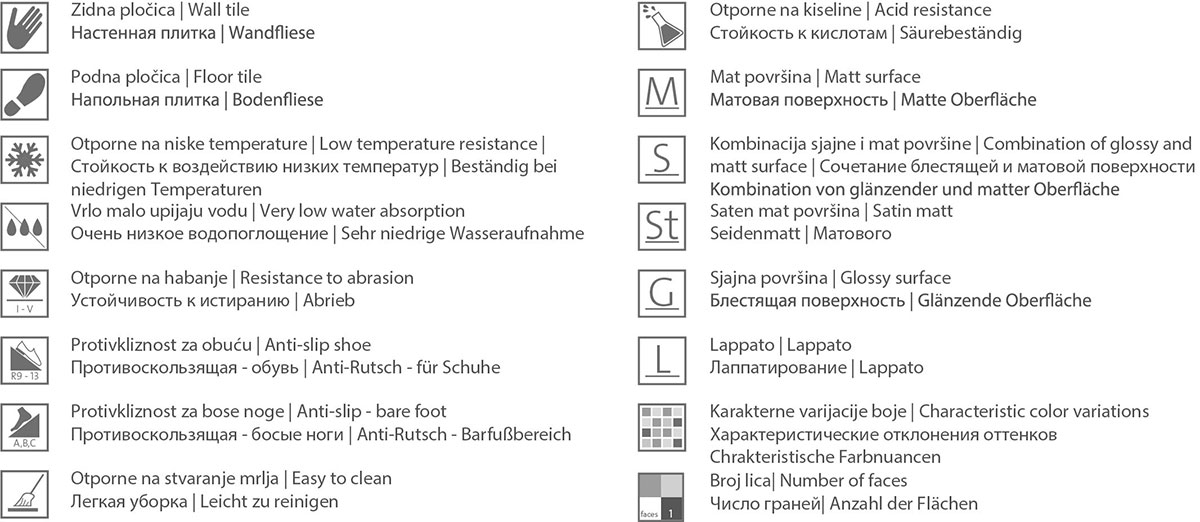

Explanations of symbols